Tung Yang Tymico Stenter and Washing Machines

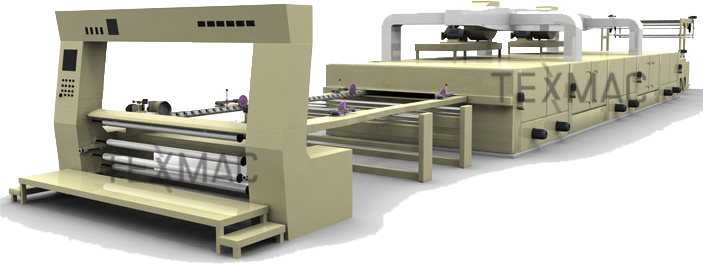

TY-TNT

Tung Yang Hi-Air Computerized Stenter

Features:

- Integrating both American and Japanese technologies, TY-TNT has evolved into new levels, giving customers great quality in fabric finishing.

- Central PLC control with Touch Screen Panel

- Each chamber equipped with individual motor for width adjustment

- Chain running speed can run up to maximum of 120m/min

- Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

- Market successfully over 30 years

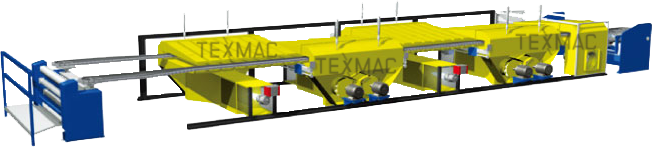

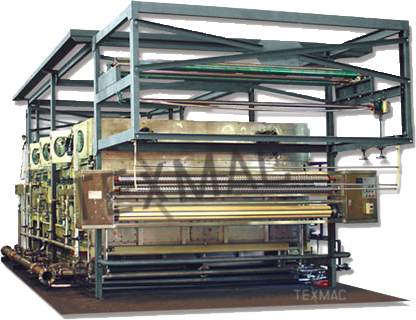

TY-WTNT

Watetsu Hi-Echo II Computerized Stenter

Features:

- Servo Amplifier and Servo motor control, accuracy far over exceed the use of traditional inverter control.

- Main drives are control separately by two servo amplifier and servo motors.

- Machine is manufacture completely from Japanese drawings.

- Main electrical components are completely ship from Japan.

- Chain running speed can run up to maximum of 150m/min.

- Each chamber equipped with individual motor for width adjustment.

- Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

- Market successfully over 10 years.

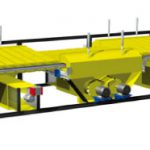

TY-MW

MARSHALL & WILLIAMS P5V STENTER

Features:

- Unique vertical rail design especially for processing knit fabrics..

- Machine is manufacture completely from American drawings.

- Dual Air Circulation System

- Large side door to be accessible for easy and efficient maintenance.

- Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

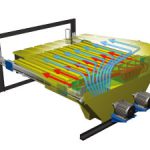

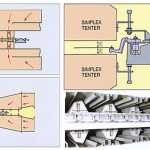

TY-Hirano

Hirano Simplex II

Features:

- Capacity of Drying or Setting 30-50% up

- Saving Energy 25% – 35% down

- Most compact in the World.

- Epoch-making telescopic nozzle

- Minimum distance between fabrics and nozzle.

- Unique floating system.

- Hot air nozzles extractable for easy maintenance

- Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

- Market successfully over 25 years

TY-TKHS

Tung Yang Tubular Heat Setting Machine

Features:

- Overfeeding roller made by special rubber which can avoid the friction and waffle effect by the frame

- The entry frame is comes with Bakelite roll and P.U roll which make the fabric smoothly entering the heating chamber.

- Accurate air speed and heat temperature to produce better result in machine performance.

- The thermo control system comes with accurate air speed with great circulating system and heat control to make the machine safety and temperature stable.

- Market successfully over 30 years.

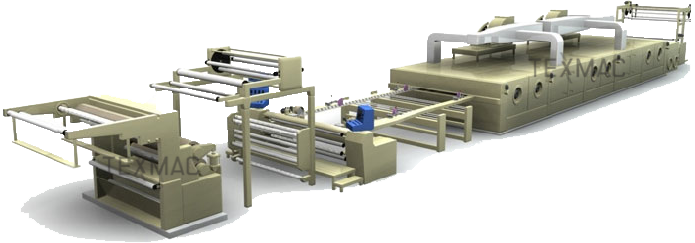

TY-NSD

Tung Yang No-Tension Shrink Dryer

Features:

- One Axial “Hi-Air” Fans with inverter per chamber

- Individual speed control on each conveyor layer (Patented)

- Conveyor net is made of Nomex or Kevlar Teflon coating glass fiber

- Control by PLC for automatic conveyor net centering

- Heat conservation chamber design (Patented)

- Zig zag nozzle design G. Heat source choices are high pressurized steam, LNG or LPG, and Thermo Oil

- Market successful over 30 years

TY-Hanayama

Tung Yang WASHING MACHINE FOR KNIT

Features:

- Utilize large size individual temperature control drums and sinking tanks. Special for natural shrinkage of fine knitted fabric, such as lycra and spandex.

- Each drum’s temperature can be unilateral control and maintain..

- Each drum can be individually control for speed adjustment, between each drums -3% to +10%, depending of the fabrics.

- Computer control with 99 sets of memories settings for easy quality maintains.

- Water flows in opposite direction of fabric transport direction. Carrying all dusts away from the fabrics more efficiently.

Tung Yang Tymico Stenter and Washing Machines

Previous

Next

For Inquiry please contact :

+ 66 (0)34 102589

info@texmac.co.th